Check out our New Products section!

Lage Manufacturing, L.L.C. Frequently Asked Questions:

The manual can be downloaded HERE

The MAX-11 mk2 uses double stack, single feed, 32rd steel magazines. They can be purchase on our website HERE.

You can also use plastic Zytel or Pro Mags, but we recommend metal magazines for their reliability and durability.

The M31 Drum Magazines are available from a few online stores. Their condition and price can vary greatly.

We have found the following online stores to have a regular stock of the 72rd Suomi Drum Magazines:

Clearview Investments sells used drum magazines. As of 9/28/21 their prices are $84.99. Their website is wwww.clearviewinvest.com and the magazines can be purchased at https://www.clearviewinvest.com/suomim31.aspx

Please note: The 36rd Suomi Stick mags will not work in our Uppers without major modification. However, 50rd "Coffin" magazines will work, but they are a hard to find item. You will most likely find these at gun shows or gun auctions , if you're lucky. We also sell 30rd Stick Magazines that were made specifically for these Uppers HERE

Yes, they will work without any modification.

We sell an Internal Gas Block that works with our MAX-11 mk2 and MAX-31 mk2 Uppers to reduce the amount of gasses directed towards your face when shooting suppressed.

The cast OEM selector can have casting lines that may prevent it from being inserted into the sear. You can carefully file the casting lines down to get it to fit. The hole on our sear is slightly smaller, as you noted. It is designed for aftermarket CNC selectors and OEM selectors, but sometimes the OEM selectors are a little rough. It is better to have a tighter fit between the selector and sear.

Marty from Shockwave Technologies says "We designed the ZMAGs such that they will rub for some. This was intentional, as we wanted to ensure we had the bullets as high up as possible as the bolt strips them from the magazine. If your bolt still closes with the ZMAGs inserted, you should be good to go. The only hiccup we've seen is where a ZMAG might sit too high in a particular gun such that the bolt hits the feedlips and stops dead in its tracks. Obviously, that's not gonna work. Work your bolt over an empty mag 50 times. Then take it out and fire it. You'll be happy. "

The MAX-11K is a shortened version of the MAX-11 mk2 with a built in K-Grip. The rate of fire is slightly faster too. The benefit is that it is more compact and some people prefer the slightly faster rate of fire. The benefit of the MAX-11 mk2 is the slower rate of fire and a bottom rail for mounting a forward grip.

Here are the exact comparisons:

MAX-11K rate of fire is about 740 RPM and can be increased up to 1140 RPM with VBS-3. MAX-11 mk2 rate of fire is about 670 RPM and can be increased up to 950 RPM with VBS-3.

MAX-11K is 3" shorter (12.23" long versus the MAX-11 mk2's 15.21").

MAX-11 mk2 has a built in foregrip with a bottom rail that allows you to mount grips. MAX-11K has a built in K-Grip with no bottom rail.

MAX-11 mk2 has an 8" barrel threaded 1/2-28 with a birdcage flash hider. MAX-11K has a 5-3/4" barrel threaded 1/2-28 with a bullnose thread protector.

Hold the pistol grip with one hand and squeeze the trigger and hold it back. Keep holding the trigger back through the following steps.

1) Place the muzzle, pointing down, on a workbench and give the back of the upper receiver a sharp slap to seat it all the way rearward.

2) Then give a sharp slap to the bottom of the foregrip.

3) Then pull it up and forward to remove.

If it still hangs up, you will need to remove the sear and selector while it is still on the gun. To do this, rotate the selector to a vertical position with the pointer pointing up. Use a punch on the opposite side to drive the selector out. Once it clears the sear, the selector will pull free easily. The upper receiver should be able to be pulled off the lower receiver. When the upper is removed, watch out for the loose parts that will fall out. The sear, sear spring, trip and retainer spring will be loose.

The most likely problem will be a malformed selector/sear retaining spring. When installed, the "L" shaped end towards the front of the lower should sit 3/16" below the top edge of the lower receiver. Also, inspect the lower receiver to see if there is any weld build up around the retaining pin reinforcement. Excessive weld could be binding the upper.

The Sten magazines are inexpensive, but due to the many manufacturers they vary in dimensions.

The Sten conversion is compatible with our Uppers, but you may have to sort out which Sten mags work best or adjust the feedlips to get reliability.

Sten conversions were popular when the magazine ban was in effect.

The conversion increases the size of the grip, which is already blocky and uncomfortable.

I recommend leaving the magwell alone and purchasing the steel magazine

You can use a variety of ammunition but we tend to use Magtech 95 gr. FMJ. We have found this ammo to provide reliable feeding and the most consistent results for reliability.

The Powder Springs M-11A1 will work with some of the parts we make. The magazine well on the Powder Springs version was made smaller and will only accommodate the .380 mags. Since the magwell is smaller, you will need to make sure that you select the 2 pc. Molded Grip that specifically states that it is for the M-11/380 Small Magwell. You will still be able to use the MAX-31A mk2 with this smaller magwell since the magwell is moved forward to use Drum Magazines. You can also use the MAX-11A1/380 mk2 Upper Receiver.

If you want to put a Suppressor that came with your M-11A1 (assuming it has an original barrel) on to the MAX-11A1 or MAX-31A mk2, then you need an adapter to go from 1/2-28 to 5/8-11. Since you will be using a suppressor designed for .380 ACP with 9mm ammo, you need to consult with the suppressor manufacturer to insure it is safe to do so.

The cast OEM selector can have casting lines that may prevent it from being inserted into the sear. You can carefully file the casting lines down to get it to fit. The hole on our sear is slightly smaller, as you noted. It is designed for aftermarket CNC selectors and OEM selectors, but sometimes the OEM selectors are a little rough. It is better to have a tighter fit between the selector and sear.

Aftermarket double feed magazines for the M-10/9 may have their magazine catches malformed resulting in two notches instead of one.

This results in the magazine sitting higher and interfering with the bolt traveling over them when stripping a round.

You can test the fit of your magazines by inserting an unloaded magazine in your gun with the bolt forward. If the magazine locks in, then it may be the correct height.

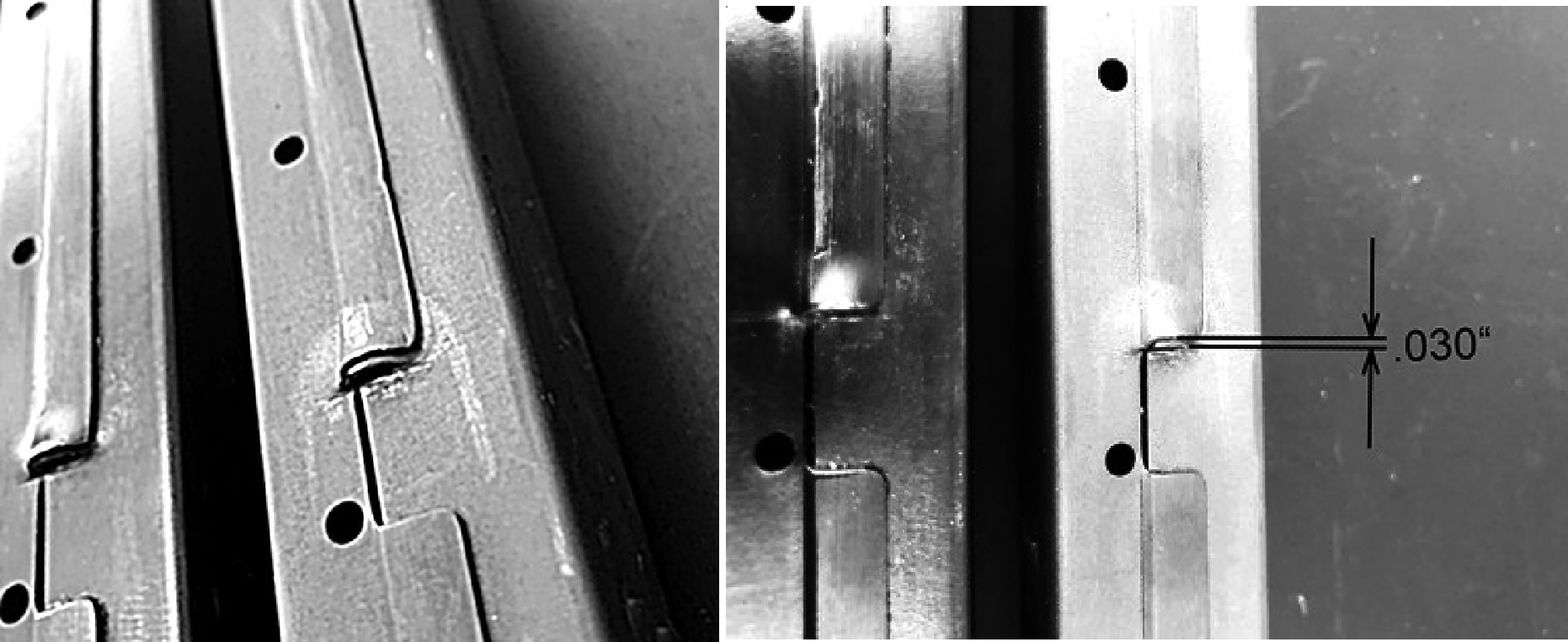

Cock the bolt back and observe the distance between the feed lips of the magazine and the clearance cuts in the bolt. The bolt should just clear the feed lips without rubbing. A .030" gap is permissable, but the closer the feed lips are to the bolt, the better performance you can expect.

Next, cock the bolt back until it is held by the sear. Try to insert the magazine further, then tug down on it to make sure it is seated. While holding the bolt charging handle, pull the trigger and release the bolt, slowly easing it forward. While doing this, carefully observe the path of the bolt relative to the magazine feed lips. If the bolt collides with the feed lips or back of the magazine, then the bolt is now sitting too high. This is a result of two magazine catch notches inadvertantly being formed in the magaizne during the manufacturing process.

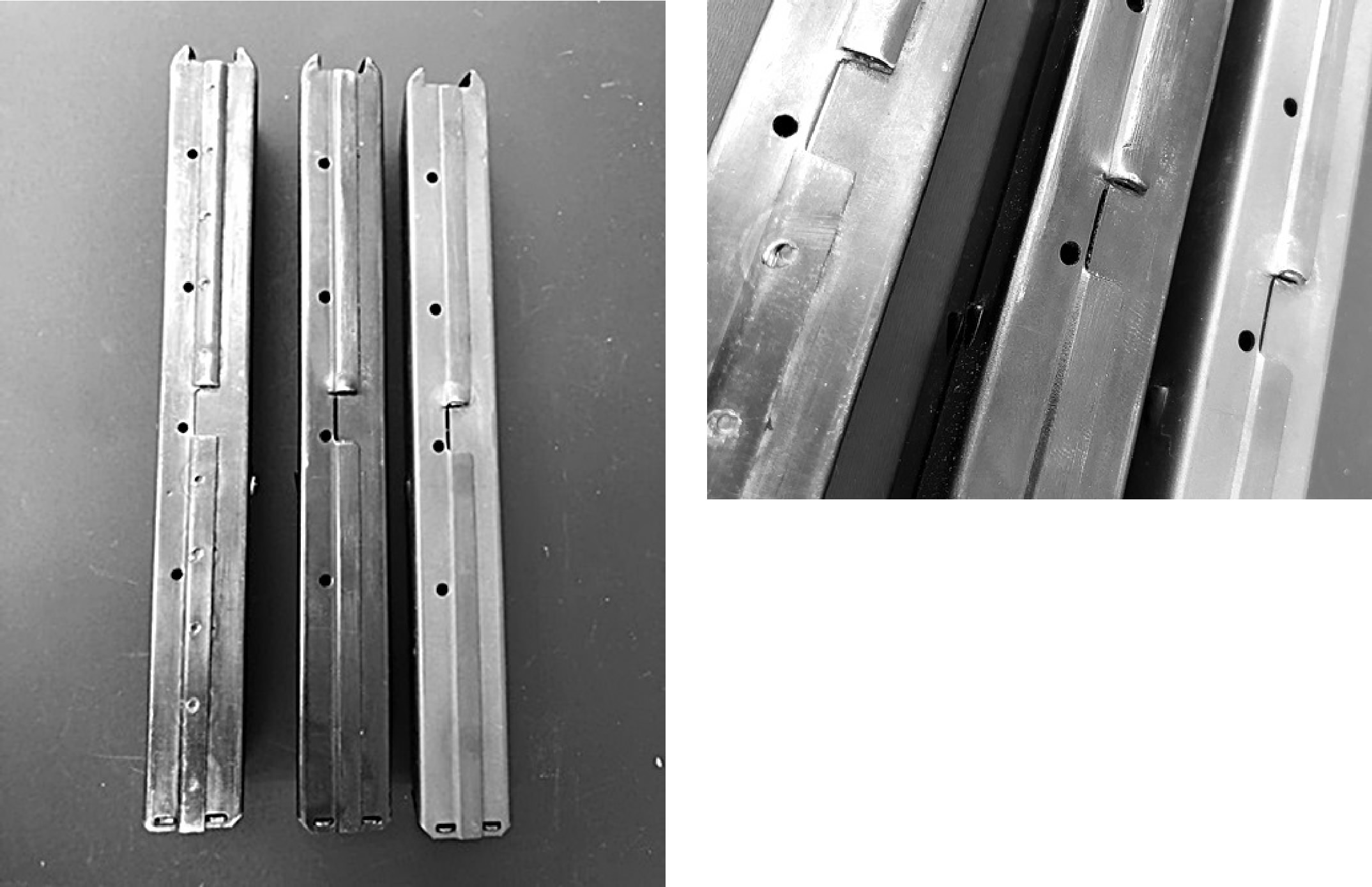

The photos below show an OEM style magazine on the left and two aftermarket magazines to its right. You will notice that on the OEM style magazine, there is a raised rib along the back edge that is spot welded. Also, the magazine catch is cut square.

The aftermarket magazines have a tab that is bent upwards to provide a ledge for the magazine catch. On the aftermarket magazine on the far right, you will notice that the folded edges do not line up and cause a secondary ledge or catch. This feature is what can cause the magazine to sit higher than it should.

In the photos below, you can clearly see the magazine catch defect on the magazine on the far right.

This can be remedied by removing the lower notch using a Dremel Tool with a cut-off wheel.

We do not make a .22 kit for the M-10 or MAX-10. We regularly refer inquiries for M-10 .22 kits to Sam at Practical Solutions. www.macmachineguns.com

None of our M-10 Stocks work with a Jersey Arms M-10. Our Stocks were designed for SWD (Cobray), RPB, Powder Springs or Texas Leatherwood M-10's. Sorry.

For M-10/45 Magazines:

Jerry Prasser at Recon Ordnance. His website is www.reconord.com , but he prefers to help customers over the phone, (920) 922-1515. His price is $45.00 for a 32rd magazine.

Unmodified Greasegun magazines can be purchased from www.subguns.com or www.keepshooting.com

Yes, but you will need to send your Double Feed bolt assembly to Sam at Practical Solutions to be modified. For pricing, please contact Sam at Practical Solutions.

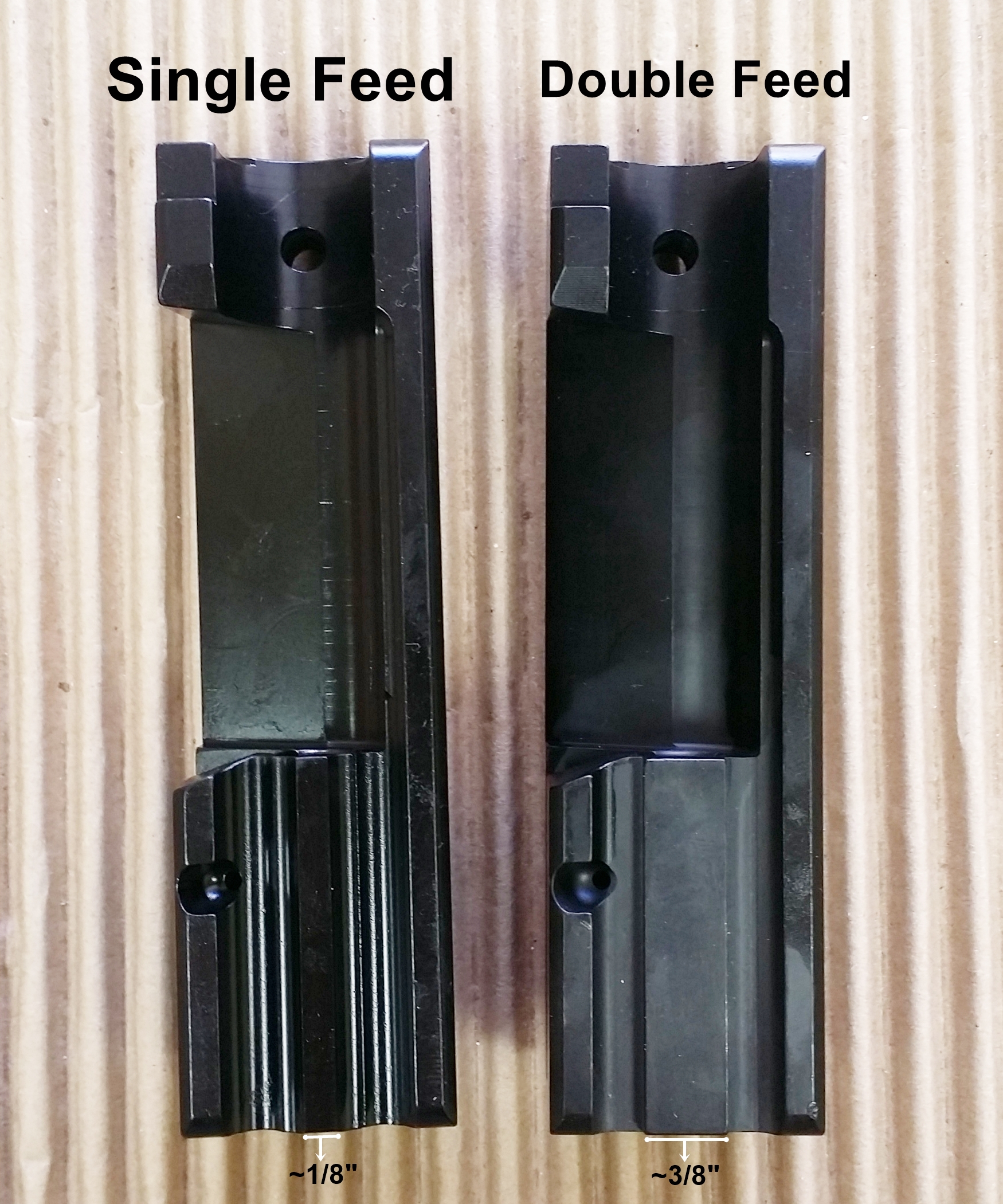

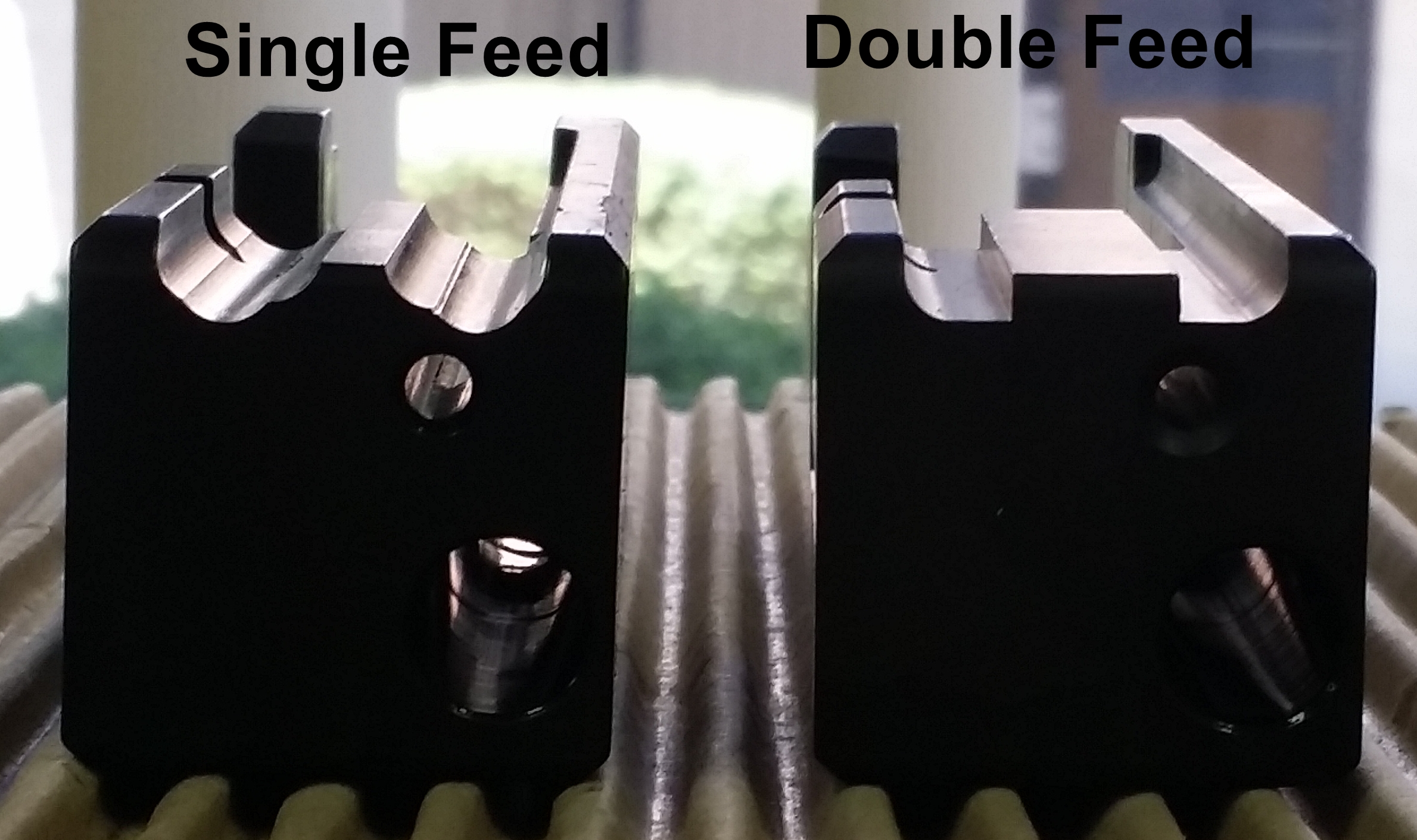

Yes. You will need to decide whether you would like use single feed or double feed magazines.

Here's what you need to convert it:

Double Feed:

The MAX-10/9 mk2 Double Feed Upper Receiver.Drop in Magwell adapter from RPB Industries. It's not listed on his site, so call him at (404) 326-6798.

M-10/9 Double Feed Metal Magazines from RPB Industuries.

OR

Single Feed:

The MAX-10/9 mk2 Single Feed Upper Receiver.Drop in Magwell adapter from our website.

M-10/9 Single Feed Magazines.

For magazines, you would use steel single feed M-10/9 magazines. Jerry Prasser at Recon Ordnance sells them. His website is www.reconord.com , but he prefers to help customers over the phone, (920) 922-1515. You can also use Single Feed magazines that are plastic but we do not recommend them. This is one reason many people prefer the double feed option. The plastic magazines are either the original Zytel or Pro Mags. While they are very inexpensive, the feedlips are known to wear down. We do sell Feedlip Kits to repair them for when that happens.

In addition, you would need one of our M-10/45 to M-10/9 Single Feed Magazine Catches.

Yes, but you will also need a magwell adapter and 9mm magazines. We sell these on our website HERE.

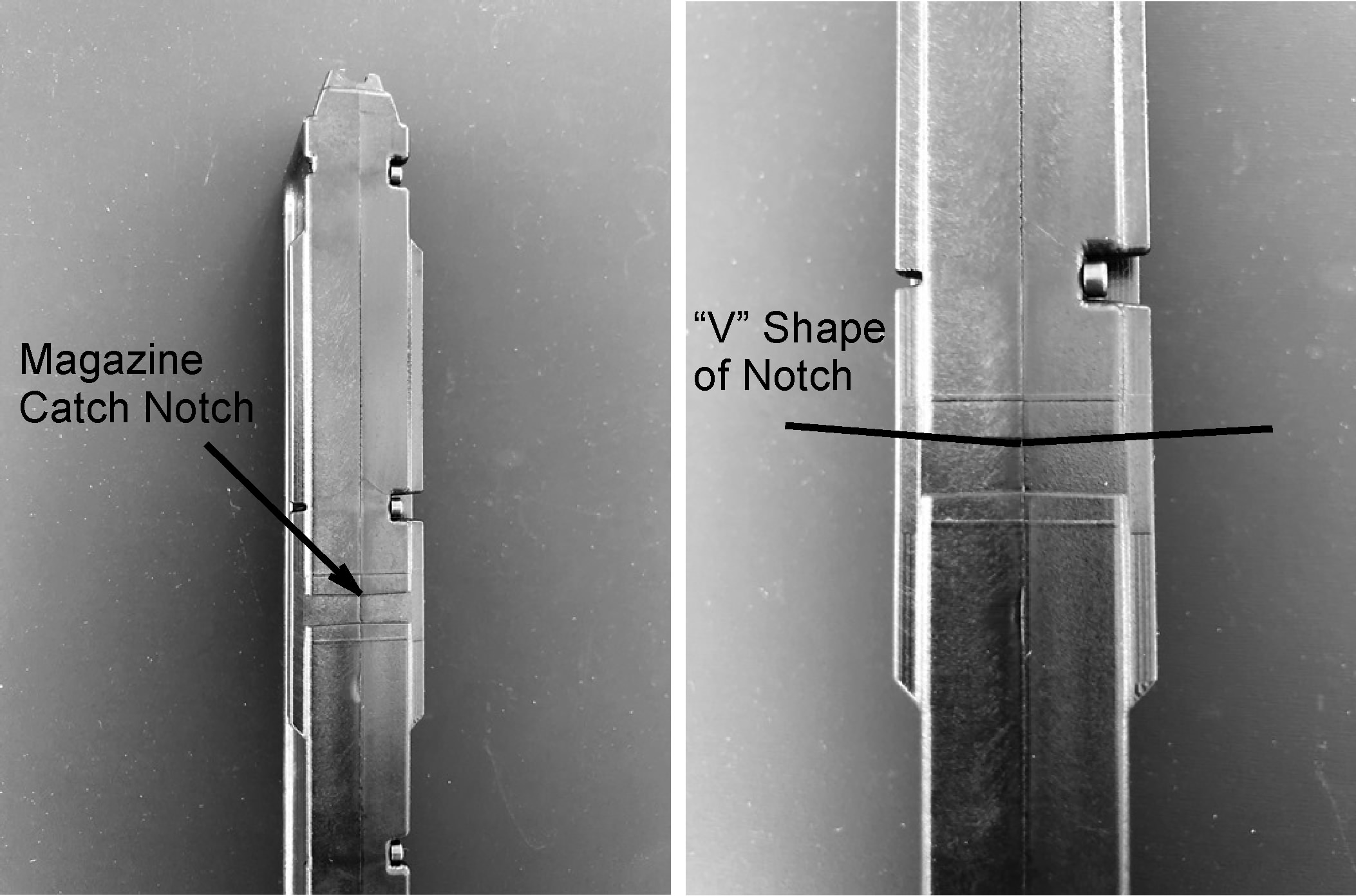

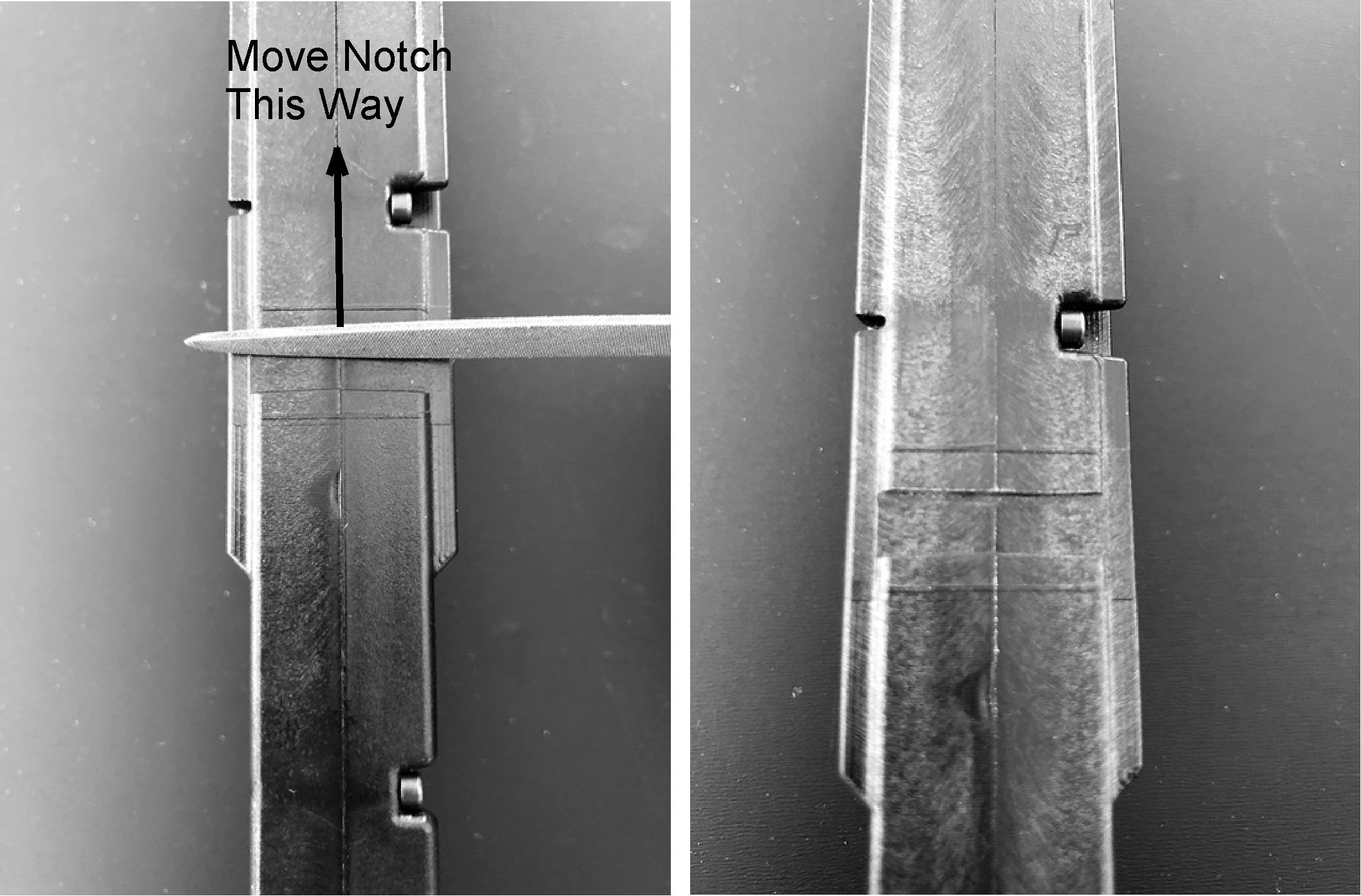

Please refer to the pictures below:

Yes, we offer sten magazines for the .22 kit. Just let us know you will be using it in a sten modified gun when placing your order.

You can use a 9mm suppressor with your .22 kit without a problem. If you plan on using a .22 suppressor with your .22 kit, you will want to thread your .22 barrel to accept the suppressor. When ordering your .22 kit, please let us know that you will need a .22 barrel long enough to be threaded. We can provide a longer barrel if necessary. We do not offer threading services but USMachinegun.com does and they are down the street from us. They can be contacted at http://www.usmachinegun.com/ . TROSUSA.com is also familiar with our kits and offers threading services.

The Lage Manufacturing L.L.C M-11/22 and MAX-11/22 .22 Conversion Kit is designed to position the magazine feed lips as close as possible to the centerline of the bore. Due to variations in the maufacture of the upper and lower receivers, some .22 magazines may not lock in tight, or in rare cases, may not lock in at all.

To test the fit, insert an unloaded magazine into the magazine well and attempt to seat it. Look through the ejection port and make sure that the magazine feedlips are touching the steel feedlips of the kit.

If the magazine does not lock in, lightly bump the bottom of the magazine with the palm of your hand and see if that seats it. If it does, release the magazine and try it a couple of more times. The magazine catch notch on the the magazine is molded at a slight angle from both sides resulting in a shallow "V" shape. The tip of the "V" will wear in.

If the magazine still does not lock in, take a file and remove a very small amount from the magazine catch notch on the back of the magazine. .020" will make a big difference. File a little and then check the fit. Remove a little material at a time until you can get the magazine to lock in.

After inserting the magazine, you should not be able to pull out the magazine without depressing the magazine release. Try it with one magazine until that magazine works, then modify the rest.

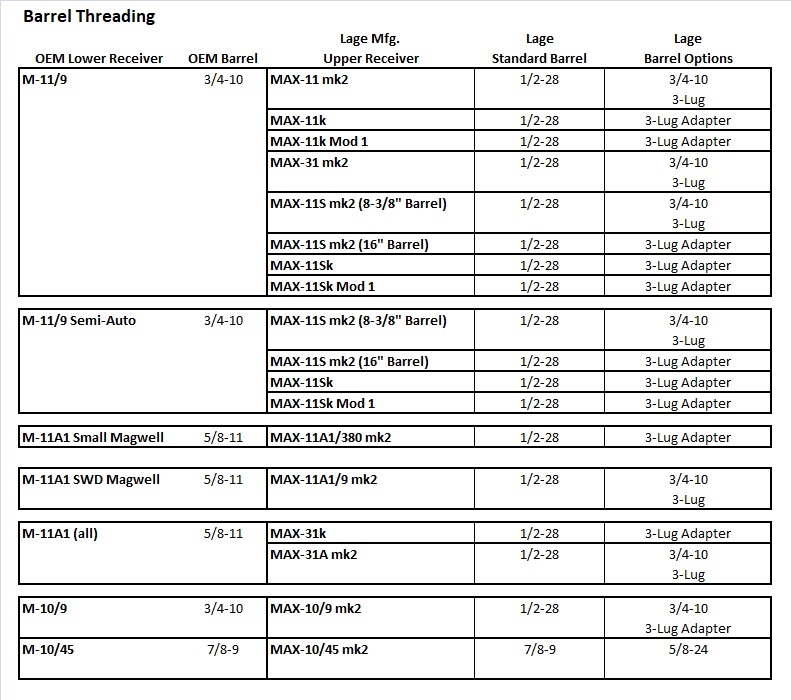

Please refer to the Chart below:

We highly recommend the use of steel magazines over plastic. Plastic magazines are cheaper, but they do not perform as well since feedlips get worn down and you will either need to replace the magazine or repair them with one of our steel feedlip kits.

SWD M-11/9 (MAX-11, MAX-11 mk2, MAX-11k) and SWD M-11A1 (MAX-11A1/9, MAX-11A1/380, MAX-11A1/9 mk2, MAX-11A1/380 mk2) : We carry Shockwave Technologies magazines. We have found these to be of the best quality and reliability. We stock 30 round and 50 round M-11/9 magazines HERE. If we're out of stock, you can also purchase them directly from Shockwave Technologies. You can also use plastic Zytel or Pro Mag Magazines. These will NOT WORK in the RPB M-11/380 lowers.

RPB M-11/380 (MAX-11A1/380 mk2): You can purchase Metal Magazines from our websiteHERE.

MAX-31, MAX-31 mk2, MAX-31A, MAX-31A mk2, MAX-31k : You can purchase drum magazines from Center Fire Systems or Numrich Gun Parts. Coffin magazines can be purchase from Folke Myrvang on Subguns.net classifieds.

M-11/22, MAX-11/22 or MAX-11/22 mk2: Our .22 kits use proprietary magazines. They can be purchased on our website HERE for $40.00 each. They are 40 round magazines. Though they are plastic, they have been designed in a way that the feedlips do not get worn down.

M-10/9, MAX-10/9, MAX-10/9 mk2: Double Feed Magazines can be purchased on our website.

Single Feed Magazines: You can purchase steel single feed M-10/9 magazines from Jerry Prasser at Recon Ordnance. His website is www.reconord.com , but he prefers to help customers over the phone, (920) 922-1515. You can also use Single Feed magazines that are plastic but we do not recommend them. The plastic magazines are either the original Zytel or Pro Mags. While they are very inexpensive, the feedlips are known to wear down. We do sell Feedlip Kits to repair them for when that happens.

M-10/45, MAX-10/45, MAX-10/45 mk2: Unmodified Greasegun magazines can be purchased from www.subguns.com or www.keepshooting.com They are inexpensive magazines that can be used with the addition of one of our M-10 Dual Magazine Catches. Regular M-10/45 magazines can be purchased from RPB Industries or Recon Ordnance.

Check the places listed below. Availability changes all the time since Machine Guns are no longer legal to manufacture for citizens. You may have to "hunt" for a while to find the one you are looking for.

1. Midwest Tactical - atfmachinegun.com

2. Ruben Mendiola - dealernfa.com

3. Trading Post on Uzitalk.com

4. Sturmgewehr.com

5. Gunbroker.com

6. Gunspot.com

7. Dennis Todd 610-543-7300

The speed buffers shorten the reciprocating of the bolt (A.K.A. Short-Stroking) thus increasing the speed. They are ok to use. For the M-11, MAX-11, MAX-11k, MAX-11 mk2, MAX-31, MAX-31 mk2, MAX-31k and MAX-31A mk2, we recommend using one of our VBS (Variable Buffer Spacers) to increase the rate of fire. For more information about the rates of fire that can be achieved with the VBS, please see the information listed under the page for the Upper you want to use with the VBS.

The number of VBS you can fit in an Upper along with the approximate rates of fire will be listed under the VBS section on the page for that specific Upper.

The Legacy Uppers hold the same amount of VBS as listed for the mk2 Uppers but the rates of fire will be slower than listed for the mk2 Uppers

None of this ammunition is recommended for use with our Upper Receivers. They can cause problems ranging from feed jams to squib rounds that will ruin your barrel.

Reloaded ammunition, Remanufactured ammunition, and Aluminum Cased ammunition will void the warranty.

The recommended ammunition for all of our Upper Receivers is a Full Metal Jacket Round Nose bullet.

The recommended ammunition for the .22 kits is Remington Golden Bullet Plated Hollow Point, CCI Mini Mags or CCI AR Tactical Copper Plated Round Nose.

Mac-11.info has a wonderful color coded guide on how to remove and install the entire fire control group HERE.

For the M-11/9, we like the Gemtech MK-9K

For the M-10/45, we do not have a recommendation but many customers have told us they are happy with the Advanced Armament Corp. Ti-RANT .45

Other options to look into are the Gemtech Viper ,which was made specifically for the MAC, and Bowers Vers 45 and Vers 9S which were also designed specifically for the MAC.

We do not accept customers' firearms. Our parts are designed to be added to your gun without needing a gunsmith. If you are running into fitment issues, please e-mail or call and we can troubleshoot any issues. If the fitment problems are related to your gun, we can recommend a gunsmith that specializes in MACs.

Yes, but you will not be able to use the iron sights. The folding stocks sit higher than the standard collapsible stock. We also make the "OEM" Folding Stock for use with the original Uppers. If you have a scope rail on top of your OEM upper, any of our stocks will work with it.

Sorry, we do not offer any discounts.

Yes, we offer dealer pricing on select products. Please e-mail a copy of your FFL to sales@max-11.com for a list of products that we offer dealer pricing on.

Lage is Richard Lage's last name. Our family pronounces it so it rhymes with cage, page, etc. In German, it would be pronounced La-guh.

The issue you are experiencing with the selector may actually be caused by the previous owner uninstalling the trip or installing it incorrectly. If you simply take out the trip, then your gun will run full-auto all the time whether you have the selector on semi or full. Also, check if your Sear has been modified.

-The MAX-11, MAX-11k, MAX-11A1, and MAX-10, MAX-31, MAX-31k and MAX-31A Uppers will work in both Full-Auto and Semi-Auto.

-The .22 conversion kits do not work in Semi-Auto.

If you are using metal Recon Ordnance Magazines, then you have to have the Collapsible Stock extended when inserting the mag.

Place an empty shell in the chamber and close the bolt on it. With an empty magazine in the magwell, slowly pull the bolt

back and see if the shell comes free prior to hitting the ejector rod. Sometime the extractor hook rests on the outside edge

of the rim instead of gripping around it. The shell does not need the extractor to clear the chamber, but it will not "flick" clear

of the gun if the extractor does not hook around the rim. Try it a couple times to verify it is or is not working correctly.

Extraction issues can also be caused by ammo or mags rather than the extractor itself. Try different combinations of magazines

and ammunition.

If you are still having issues, then you may need a new extractor.

Please check for weld build up inside the back rear top of the lower receiver. There may be marks from it digging in to the rear upper receiver slots. If there is excess weld, it can be carefully removed with a jewelers file. Also, check for any other rub marks on the bottom of the upper receiver to see where the interference may be. If you have an aftermarket stock installed, make sure that the stock latch is not sitting up high enough to interfere with the upper sliding in. Finally, if you lower has a 83- or 84- serial number, it may have an odd stock carrier welded in place. Check for rub marks on the bottom rear of the upper receiver. Also, make sure the gun is unloaded and the safety is off when putting the Upper on.

Runaways can be caused by a couple of things:

1) Weak ammo can short stroke the bolt, not allowing the bolt to catch the sear.

2) Check the sear notch on the bolt to see if it is worn or rounded. On the MAX-31, MAX-31 mk2, MAX-31A, MAX-31A mk2 and MAX-31k

It is located by the bolt face, not at the front like the OEM M-11/9 bolt.

3) Check for a bent ejector rod or recoil rod. If the bolt has been dropped, the rods can get bent causing friction.

To check for straightness, remove the rods and roll them on a flat surface. Look for any wobbling. Also, look for any shiny, worn spots on one side. The rods can be straightened and re-used.

4) Clean the upper and look for any obstructions that may be rubbing on the bolt.

The answer to this question is dependent on the type of jam you are experiencing. Please select which type of jam you are experiencing.

- Bullet tip is hitting the barrel (Feed Jam) This can be caused by hollow point or flat point ammunition. We recommend using full metal jacket, round nose ammunition.

You can adjust the feedramp up to eliminate the bullet tips jamming on the barrel edge. To do this, remove the fire control parts and place a couple of layers of tape on the feedramp to protect it. Place an adjustable wrench on the feedramp and close the jaws down on it. Pry up a little and then check the height by placing the upper on the lower without the bolt assembly installed. Place your "pinky" finger in the ejection port and slide it up the feedramp and into the barrel chamber. You should feel a smooth transition. If it is not, use the adjustable wrench again to move it higher.

- Stovepipe Jam or Extraction Jam

This type of jam is usually caused by weak ammunition or bad magazines. Try using Federal WM51991 115 gr. or S&B 115 gr. ammo. Make sure your magazines are not over-inserted by tugging thme back down after inserting and amke sure the bullets are sitting properly in the feedlips. They should be slanted upwards at approximately a 7 degree angle. Also, make sure your magazines are clean.

If these tips didn't help, please call or e-mail us so we can help you troubleshoot the issue.

Our Sear is manufactured with a tighter selector pin hole tolerance than the OEM one. Your particular gun may have needed this extra play to work correctly.

The gun burst firing in the full auto mode is usually caused by the trip rubbing on the bottom of the bolt, when the gun is set to full-auto.

If you remove the trip and fire the gun, it should shoot full auto without interruption.

You should be able to verify the trip is rubbing by manually cycling an empty gun. Set the gun to "Semi" and hold the trigger back hard while you cycle the bolt back and forth.

You will feel the trigger get pushed forward a little or light resistance on the bolt from the trip. The solution is to remove a little material from the front top of the trip, where it contacts the bottom of the bolt.

File or grind off about .020" and check to see if the trip is rubbing when in semi-auto or test fire it to see if it is functioning correctly.

Please check the following:

1) Make sure the extractor is not missing. If not, check the extractor hook to see if it is worn.

2) Make sure the extractor spring is not missing. If not, check the extractor spring tension to make sure it has not weakened.

3) Disassemble the extractor from the bolt and clean out any built up carbon fouling underneath the extractor.

4) Check the recoil rod and ejector rod and make sure they are not bent. Look for any shiny spots on the rods to see if they are rubbing.

Remove the rods and roll them on a flat surface to see if they wobble. The rods can be straightened and re-used.

5) Check the bolt face to make sure it is not damaged. An out of battery can crack the lower lip of the bolt face.

6) Check the barrel chamber to make sure it has not stretched. Insert an unfired bullet backwards into the chamber. It should only be able to inserted about half way.

If it can seat on the ridge for the case mouth, the chamber is stretched.

Please make sure that you are not getting rim lock when loading the magazines. Rim lock is when the rim of the round being loaded into the magazine slips behind the rim of the round underneath.

This causes the bullet to be slowed down during feeding, because it has to overcome the rim underneath. It basically acts as a speed bump.

For ammo, I recommend high velocity plated 40 grain .22 long rifle. Specifically, Remington Golden Bullet or CCI Mini Mag.

With a side cocking upper, it is important to hold the cocking knob forward when firing. Otherwise, the cocking knob can move rearward and the .22 bolt will crash into it on the forward stroke.

Besides peening the bolt, this can rob energy from the bolt and cause misfires or feed jams.

It is fairly easy to shoot with your left thumb resting on the cocking knob to hold the cocking knob forward.

As long as the bolt freely moves within the upper, there is nothing to worry about. If a burr is raising, it can be filed down.